Working with wood can be a full-time profession, a hobby, a passion. Whatever it is for you, you know the hazards of working with wood. From the smallest splinter to getting hurt by a table, saw, planter, nail gun, drill press, there is a lot to worry about, if you are not careful.

See Also:

Slight carelessness can cause grave injury. Working with tools in your woodshop, you know how unsafe it could be if you’re not careful. If you have employees, then your woodshop needs to be safe, follow safety measures, and educate your employees on safety procedures.

More...

Different Machinery in your Woodshop

What is the different machinery being used in your workshop? There must be some noisy tools, saw dust which may affect your eyes and breathing, dangerous tools which may cut your finger or even hand.

Let us examine some common tools which require safety measures; there are much more besides these.

Power Machines

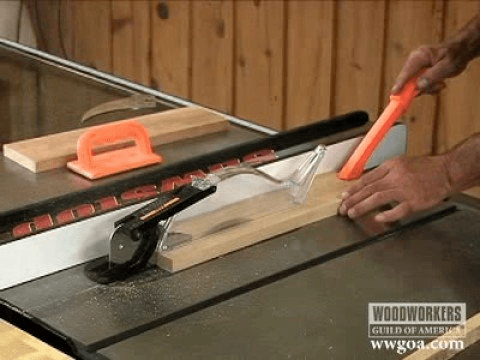

Table Saw: Fatal injuries and accidents are common when people do not follow safety measures while using a table saw.

Carpenter in wood workshop using table saw. Mature man i casual clothing. Space is full of working tools and wooden planks.

- Always wear safety glasses to shield your eyes.

- Do not wear lose-fitting clothes.

- Table should be of a right height and set appropriately to avoid the use of extreme force to cut.

- The blade height should be set to 3mm (1/8”) above the thickness of the material being cut.

- The area around the saw and cutting should be clutter free.

- Unplug the saw before changing blades or doing maintenance work.

- The material should be held down and against the fence when you are making a cut.

Band Saw:

- Remove any jewelry and avoid lose-fitting clothes.

- Confine long hair

- Use proper eye protection geard.

- Never back out of curved cuts when your machine is running; wait for the blade to completely stop.

- Your hands should be on the sides of the blade when operating. Do not ever place your hands in front of the blade.

- Feed wood into blade firmly but not too hard.

- Stop the saw immediately if the blade breaks.

Sanding Machine: This can cause serious burns when handled incorrectly

- Wear safety glasses.

- To avoid any fire or explosion, keep the dust extracting system turned on and connected to the sanding machine.

- Before plugging in a portable sanding machine, make sure that the switch is off.

- No liquids near the sanding machine.

- Fingers must stay away from the moving belt.

Drill Press:

- The power source must have the same voltage supply as specified in the manual for the drill press, else it may cause serious injury.

- No tripping obstacles around

- Lightning must be adequate.

- No rags, loose clothes, cord or strings should be around the area

There are several other power machines in your woodshop like a planer, jointer, and mortise machine and bench grinders. Make sure to read their respective manuals before operating them and follow all safety measures.

Portable Power Equipment

Injuries (dangerous work) in woodworking manufacturing. Saw tool work risk

Portable Power Saw: These are commonly used in homes, garages, and factories. They have a very high-powered blade which can easily slice the wood.

- You must wear protective eye glasses.

- Control your saw and the piece to be cut; secure the wood with plastic clamps. Thin pieces can move causing serious injury.

- Make sure that a skilled and qualified person operates the air compressor.

- Keep check of the voltage.

- Do not work on rusted equipment as it can cause combustion.

- Do not refuel the air compressor while still running or after being shut for only a short time.

- Check for any damage before use.

- Do not use if the carbide is even slightly damaged.

- The router bit must be installed correctly, that is, ¼” of the shaft must show between the cutter head and router’s collet.

- Never touch the bit during or right after use, as it will be extremely hot.

woodworking safety via The Safety Channel

Some other portable power equipment is portable belt sander, nail gun, reciprocating saw etc. All these machines and tools need utmost care while handling. You need to follow all safety guidelines to avoid any injury or hazardous condition.

Common Rules Apply to All Machines/Tools

Wear Safety Equipment: Safety equipment to protect your eyes, face, hearing etc. are crucial to woodwork. Some equipment like routers can be extremely noisy, so wear hearing protection while working on these tools.

Wear appropriate gloves required for different tools, and when doing finishing work. Safety glasses are an all time necessary safety tool which must be worn when working in your woodshop.

Orange hard hat, earphones, goggles and gloves on a white background

Changing Blades? Disconnect Power: It must become a priority to unplug your equipment from the power circuit before changing blades or bits. Simply switching off the power does not guarantee safety.

You do not want to lose a digit or a limb to unsafe measures or a casual attitude when working in your woodshop.

Sharp Blades and Bits? Yes Definitely: You need a sharp cutting tool for many reasons. One, a blunt blade or bit can be dangerous and will produce a rough cut.

Nails, Screws, Other Metals- Check: The stock you need to cut should be free of any nails, screws or other metal; these may cause the stock to kick back and cause injury.

Work against the Cutter at all times: Remember, the cutter needs to cut into the wood, not with the wood.?

What Equipment You Are Using: Be sure that the equipment you use is the equipment you are trained on, and read the owner’s manual before using the tool.

Your Clothing Matters: When working with tools in your woodshop, it is important to wear proper clothing. No loose- fitting clothes, neck ties, scarves or jewelry.

Cleanliness: Your work area should be clean. No wood scraps, oil spills, or clutter around the work table and work area. This keeps you safe from any accidents. Your tools should be well organized and in place.

Cord: Power cords, wires, and equipment cables can cause major accidents. Tripping and falling over these are common. Make sure that the floor is clear of any cords or cables. Try to install power cord under the floor or overhead. Extension cords should have ground plugs.

Safety is the Goal: Whatever your reason is to work with wood in a woodshop or even at home, it is essential to maintain safety regulations. Working with wood can be dangerous if precautions are not taken.

Common Woodworking Tools

- Wires and cords need to be properly secured.

- Proper attire and safety equipment like goggles should be worn.

- Clean workplace is essential for safety.

- Blades should be sharp.

- Read your owner’s manual and work with equipment you are trained on.

- Keep a first aid box handy.?

?Precautions are better than cure. So, follow the safety guidelines while working on your woodshop. Any questions or suggestions/additions to these tips would really be appreciated by your comments. Work wise, stay safe!

This includes a photo of a woman wearing shop clothing, captioned “Pretty carpenter in uniform…” I teach theatre technology to college students, men and women. These safety comments on this webpage are useful, and I might have referred students to this page, except this photo caption is not appropriate. The implications are either: pretty people are unusual and noteworthy– it’s the not-pretty who typically work in these environments OR only pretty people are valued as subjects for the webpage. You know the situation– I’m not being overly sensitive– it is sexist. I suspect you didn’t even intend for that caption to be public.