What does pva mean? You must have heard about and used polyvinyl acetate (PVA) or wood glue, white glue, carpenters glue, and Elmer’s glue in the US.

See Also:

The rubbery synthetic polymer used in bonding woodwork together and as carpentry adhesive. Most people always use this for house furniture and keep it for further uses. It is low cost, dependable, and a definite necessity.

PVA glue is also used sanitary napkins, filter paper, textile finishing and also as consolidate in porous building stone, especially in sand stone. You can also use it for woodworking projects, DIY bookbinding, wood joints, paper, and glass fibers.

These products can be easily availed in different brands, colors, and types – making it very easy to find and purchase.

More...

What is Polyvinyl Acetate (PVA) glue made up of?

How is PVA glue made?

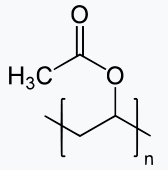

PVA is polyvinyl acetate. It belongs to polyvinyl esters family with the general formula [RCOOHCHCH2] and molecular formula (C4H6O2)2. It is a type of thermoplastic which becomes bendable, or mouldable, at a specific temperature and solidifies after cooling. Moreover, thermoplastics have high molecular weight making it a good adhesive usage.

Molecules are connected with each other through intermolecular forces and on heating, this molecular bonding becomes weaker – by changing its state to a liquid.

Thermoplastics may be reshaped and used to produce parts by different techniques: molding, injection, calendering and extrusion.

Discovery of PVA Glue

PVA glue was first discovered by the German Fritz Klatte in the year 2012. He was a German chemist. His prepared glue was odorless and safe to use with bare hands. Since then, may patent makers find ways to improve the qualities of PVA glues.

in general woodworking applications, good PVA glue needs to have:

- Strong bonds.

- Fast Set

- Dries Clear

- Non-toxic

- Does not affected by finishes

- Incredible Sandability

Types of Wood Glue

Titebond Wood Glue via amazon.com

Wood glue is available in a variety of brands, colors, types and features. You may also use it as an adhesive on clipboards, plywood, and medium-density fibreboards (MDF). Here is a quick peek of wood glue products that very much relates with PVA glue.

PVA Glue

PVA Glue via amazon.com

PVA glue is an aliphatic resin yellow in color. You can use it for wood-to-wood adhesive, which results in a strong bond and the most common type of the glue and easily available across your local stores. It can be easily scraped off from any surface by using an adhesive remover.

PVA WOOD GLUE via amazon.com

Tite bond original wood glue, Elmer carpenters wood glue, and great planes wood glue are a few examples of wood glue. It has natural colours.

Hide Glue

Liquid Hide Glue via amazon.com

Hide glue is the renowned type of wood glue, it comes from animal hides. Hide glue is chemically similar to edible gelatine and non-toxic.We can use it in musical instrument and replica furniture. It is made by heating with water.

It has a property of not interfering with finished products if in case you don’t want to remove or scrape off dried hide glue from the wood.

Bonding and assembly of furniture on the wooden pins

Epoxy

Wood Repair Epoxy Paste via amazon.com

Epoxy is another type of wood glue available in two parts – takes form as liquids – and when mixed, a chemical reaction takes place and becomes hardened, strong enough to be used as an adhesive for woods.

One good thing about using this type of wood glue is its water proof quality and itis good for filling gaps in the wood joint. It is commonly used in wooden aircraft.

Cyanoacrylate Glue

Grade Cyanoacrylate (CA) “Super Glue” via amazon.com

CA glue or super glue is a well-known type of wood glue. It is used to join hard pieces together, which can also be used in woodworking. ( here is our top picks for best super glue )

In using this kind of glue, you will only need to wait a very short time for it to cure. If you are in hurry and can’t wait for a long time then apply CA glue; there are instructions on CA glue bottles to make curing even faster.

Polyurethane Glue

Polyurethane Glue, 8 fl oz via amazon.com

You can make active polyurethane by mixing water; as a result, it swells and dries. It is waterproof and good for both interior and exterior uses.

Bonding and assembly of furniture on the wooden pins

Resorcinol-Formaldehyde

Aerodux Resorcinol Resin Kit - 1 Quart via amazon.com

We are all familiar with Resorcinol-formaldehyde adhesive glue, as it is very strong and durable. It resists to saltwater, solvents, fungus, molds and ultra violet exposure.

Resorcinol-formaldehyde requires being mixed with a catalyst powder before use.For many years it was the only recommended adhesive to use in wooden craft structures by FAA US. It was used in vintage air craft’s production.

Urea-formaldehyde

3M 20122 All Purpose Fiberglass Resin, 1 Quart via amazon.com

If you are looking for wood glue with a low effective cost, low cure temperature, high resistance to the microorganism, and light color, then Urea-formaldehyde has all the features you need.

PVA-Water-Resistant Glue

Waterproof Polyurethane Glue via amazon.com

PVA-water-resistant glue is usually used for mildew resistance and moisture resistance applications. These types can be classified into two groups: water proof and water resistant.

Titebond II and III contain water, as well as strands of polymer, which makes better adhesiveness and becomes bonded chemically to perform better on exterior surfaces. Exterior PVA glues are specially made for harsh outdoor elements. While buying PVA glue, customers are advised to read the label carefully.

Bonding and assembly of furniture on the wooden pins

What Are The Uses of PVA Glue?

Timber - Woodworking

PVA glue can be used in all types of wood as an adhesive in joint. You can use it for furniture, making doors, musical instruments, or creating your hobby projects.

You can also use it to varnish and shine wood surfaces. These uses in wood glues are applied at large scale in industries and companies.

Cement and Mortar

Uncommon to most people, PVA glue can be added to cement and mortar to give it better quality for waterproof pva. Applying these to surfaces will get you even better results, hard and strong adhesion. This is quite an uncommon use nowadays because of other types of glues.

Sand and Cement Mix

PVA glue is commonly used when mixing sand and cement. You can apply a coat of PVA before applying mortar and by doing so, you increase adhesiveness and water resistance.

Absorbent Surfaces

It can be used to coat absorbent surfaces before the application of a finish. If you are plastering over a dry surface then it would be impossible to stick a plaster over it. And to get a smooth finish and avoid quick absorption, PVA glue is a recommendable solution.

Properties of PVA GlueThe vinyl acetate reacts with boron based minerals, where its degree of polymerization is 100 to 5000. Its esters groups are sensitive to base hydrolysis and as a result, PVA converts into polyvinyl alcohol and acetic acid.

Different microorganism causes decay apaint scrapernd damage to vinyl acetate, which can be a disadvantage but this is preventable by the use of outer coatings. The decay causes by filamentous fungi, algae, yeast, and bacteria.

Brands of PVA Glue

PVA glue is available across the countries with different names, pva glue brand names, and manufacturing companies. polyvinyl acetate glue brands are different on the basis of its features – weight, volume, and price.

You can find any brand at your nearest store, however, you can also buy or place an order via amazon.com or websites of the manufacturing companies and online stores.

How to Remove PVA Glue?

There are alot of ways to remove pva glue or find the best pva glue remover available. Here are some tips you may want to consider to use:

- Use a small painting tool like a paint scraper. As if there are pva glue on the surface of the wood and sticky corners.

- Use a wood chisel to remove the pva glue. Since the wood chisel is small and can be use like the paint scraper but in different wood shape.

- Also, you may use the sanders and sandpaper to sand off like wood. If you know how to sand then just sand all the sticky pva glue away.

- Adhesive Remover can be used as support tool. You can find some other pva glue remover like liquid out there on the market to support the smooth removals.

Here is our best video that you can check out how to remove pva glue:

How to Make Strongest PVA Glue at Home?

Here is what you need to get started to make a homemade, non-toxic pva glue by yourself:

- Sugar = 300 gram

- Flour = 190 gram

- Listerine or any antiseptic mouthwash= 2 Tbspns.

- Vinegar = 3 tablespoons

- Baking soda= 2 tablespoons

- Water= 1 litre room temperature

This homemade glue can be used newspapers, fabric and to joint the cardboard pieces.

Where Can i Buy PVA Glue?

You can find it at Walmart, local art supply like Michaels or A.C Moore, or Joann Fabrics. If the color is yellow then it's okay to use the Titebond from a local home center or lumber store. In short, the quicker ways is to find it on amazon.com here.

What're the Best Wood Glues? (Wood Glues Test)

Test #1 - The Working Time Winners:

- Tight Bond III: 35 Minutes

- Better Bond: 35 Minutes

- Pro Glue: 36 Minutes

Test #2 - The Clamping Winners: ( the glue is still workable after putting the first clamp on )

- Titebond Original: 8 Minutes

- Better Bond: 7 Minutes

- Unibond One: 6 Minutes

Test #3 - Average Working Time Winners: ( after 3 tests )

- Pro Glue: 18 Minutes

- Titebond III: 19 Minutes

- Titebond Cold Press: 22 Minutes

- Better Bond: 23 Minutes

- Tightbond II: 24 Minutes

- Tightbond Original: 25 Minutes

- Unibond One: 27 Minutes

- Elemer's Glue All: 29 Minutes

To know more about their prices and how to compare, you may want to visit their company site or just simply visit amazon.com to check the current market price.

Conclusion

We came to know and understand all about PVA glue – its uses, types, brands, and properties. I have been using it for a long time and I recommend using these PVA glues in various sorts of application for better results.

It’s a simple product with many features and characteristics.There are many topics to talk about when it comes to adhesiveness. You can always use the comments section below for additions and questions if there are any. Have fun sticking!

By the way, here is a related article of pva glue - How to glue felt to wood?